Software

The heart of Brasina automates the brewing process

The heart of Brasina automates the brewing process

The Brasina software is completely designed and implemented at bitmatch GmbH in Switzerland. This includes the operating system, the field-busses, the logic up to the user interface. By doing all the implementation ourselves, we can choose the technology and are not dependent on other companies. This guarantees that any customer requests can be handled internally without relying on external parties.

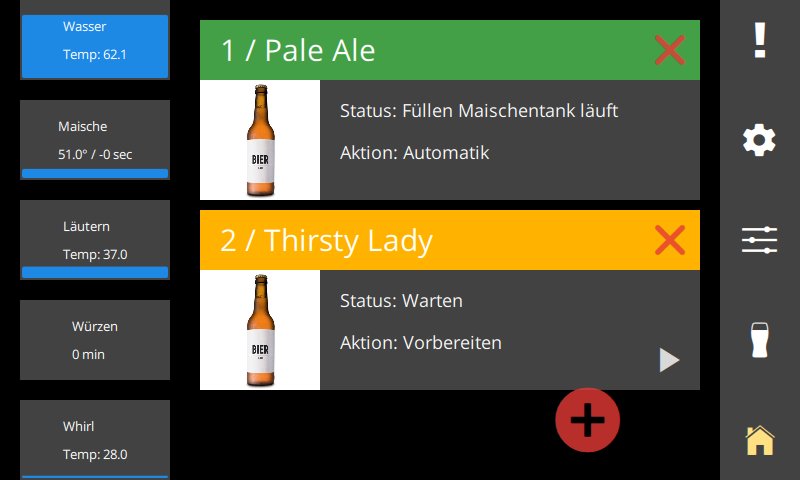

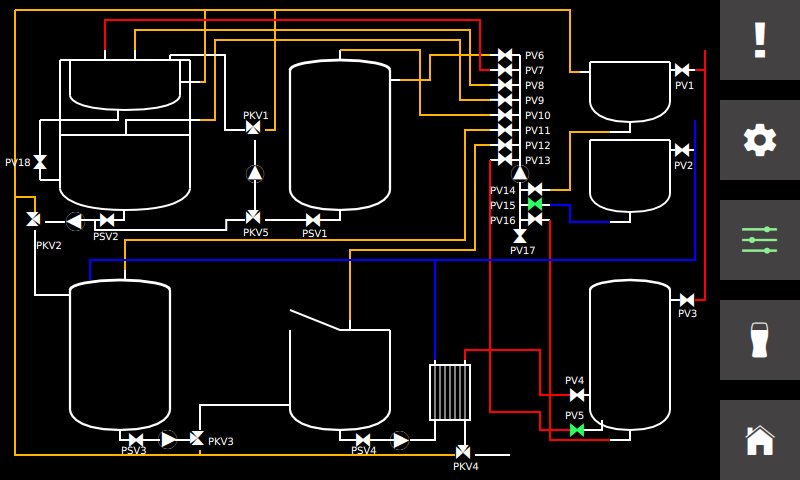

The software automates the complete brewing process. Recipes are the foundation of this automation. An unlimited number of recipes can be stored and replayed at any time. Because of an optimal matching of the software to the hardware, it is possible to run three recipes in parallel at the same time. This saves an enormous amount of time and increases the efficiency of the plant. This make Brasina very powerful while still maintaining a compact construction.

Even though the software automates most of the brewing process, it allows the brewer to override all important parameters during the process. This is useful if the brewer wants to experiment with a new recipe or wants to slightly change or optimize an existing recipes.

In addition, many settings additionally allow the software to be parametrize to any given local conditions. This is important to avoid having to change the program for each brewery.

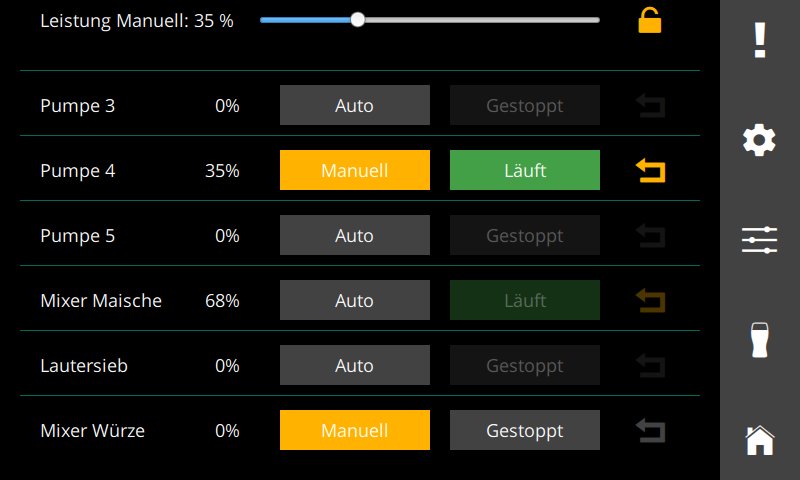

Not only is it possible to influence the automatic brewing process, but it is even possible to operate the plant manually for most parts. All motors and all valves can be changed to manual operation. The manual operation leaves complete control to the brewer and overrides any automatic requests. This make the plant even more powerful and gives the brewer complete freedom.

The Brasina software is implemented with modern and advanced technologies. The result is a robust solution, which is pleasant to use.

There are already breweries that successfully use this software each day. This, however, is not a reason for us to stop the development. We will update the software and add new useful features as well as improve existing solutions. In order for the best experience, the opinion of brewers are always taken into account and are an important factor for us. This means you can actively shape the software and its usage.

A secure remote maintenance is installed in every plant. This allows us to support the brewer should there be any problems. Through this remote maintenance, we can directly access the control system. This connection is secure and only available to us.