Hardware

Hardware used for the brewing process

Hardware used for the brewing process

Brasina consists of six stainless steel tanks. The relevant tanks are isolated, such that as little energy as possible is lost. Heating is done through thermal oil, which prevents any scorch of the wort.

The tanks are connected through an elaborate system of pipes and valves, such that the liquids can be automatically moved from one tank to another.

With this clever structure which was designed specifically for Brasina, it is now possible to run three recipes in parallel. It is no longer necessary to wait for a recipe to be complete. This saves a huge amount of time and produces much more beer at the end of the day.

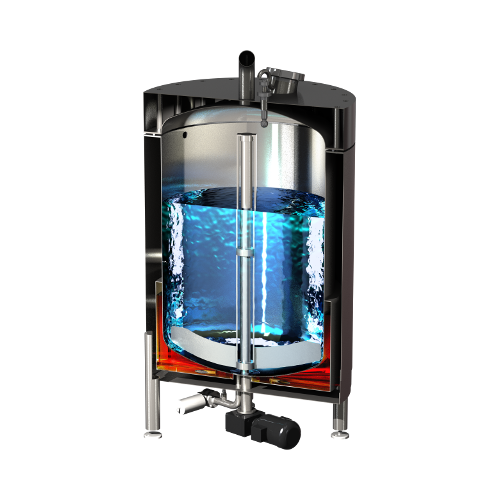

The mash tank is the first of three tanks, which are substantial for the brewing process. Malt is mixed with warm water water in this tank. Through heating up to an optimal temperature, fermentable sugar is extracted from the starch in the malt.

For this process, it is essential that the expected temperature are matched exactly, and that the temperature can be hold constant for a long period of time. With Brasina, this is achieved through the usage of thermal oil and excellent isolation of the tanks.

The temperatures and waiting times for the mash process can all be controlled through recipes in the software. This means that the process can be repeated for as many recipes as desired.

After the mash process, the wort is pumped into the lauter tun, which is responsible to clean stock. The tank consists of two parts. The upper part includes a sieve in which the wort is filled in. Because the mash has a self-filtering effect, most floating particles can be removed. During this filtration, the liquid flows in the lower part of the tank.

Brasina is designed to be able to produce many different types of beers. In order to facilitate this, many parameters of the lautering process can be adjusted.

A special feature of the design of the Brasina lauter tank is the fact that the sieve is not permanently mounted, but rotates. This achieves the effect that the wort is distributed equally in the sieve, which is an advantage for the filter process. What is more, which the rotating sieve, it is much easier to clean it after the lauter process is complete. This is achieved with a simple vacuum cleaner that has a fix position.

After the wort has been pumped from the lauter tun into the wort copper, it is heated up the boiling point. After heating, the hops can be added and cooked with the rest of the wort.

The type and amount of hop determines the flavour and tenability of the beer. As with the other tanks, Brasina allows again to fine control the hop addition and cooking times through the recipe.

After the cooking is complete, the final wort is pumped into the whirlpool. There, the no yet dissolved substances are separated from the wort. From the whirlpool, the finished wort can then be pumped into the ferment tanks. The expected temperature of the final wort is automatically controlled by the software. The regained energy from this cooling is used to heat the water in the warm water tank. The warm water can then again be used for the next stock.

In addition to the tanks described above, there are other tanks which are important for the brewing process. All these other tanks are also specified to match exactly the Brasina requirements.

In order to have enough water for the next stock, there is a large warm water tank and a smaller cold water tank. Water is dispensed in the correct mixture ratio automatically from these tank into the mash tank. This allows to start the mash process immediately.

Apart from all these tanks, there are ferment tanks and bottle machines that can be connected to the whirlpool. However, these are currently not controlled by the Brasina software, but operate autonomous. This is done on purpose, to better support already existing hardware.